|

|

|

SPECIALIZED IN INDUSTRIAL POTATO AND CASSAVA PROCESSING MACHINE FROM CHINA |

|

TONY ZHANG |

|

|

|

|

+86 185 6729 3677 |

|

||

|

|

SINCE 1991 | NANYANG GOODWAY MACHINERY & EQUIPMENT CO., LTD. |

|

SALE6@GOODWAY.TOP |

|

| Mobile/WhatsApp: +86 185 6729 3677 Email: sale6@goodway.top |

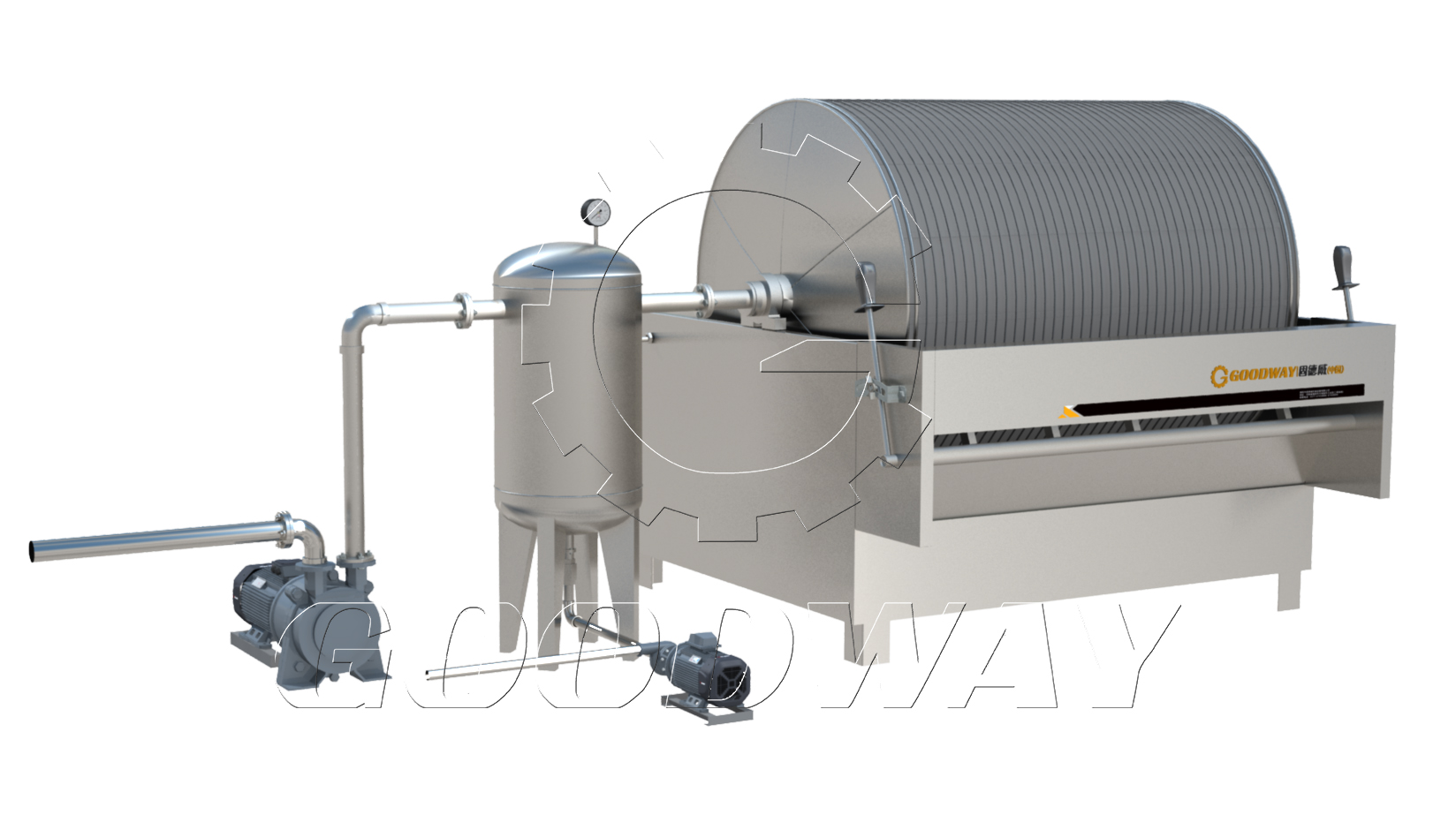

Cassava Starch Dewatering Machine - Vacuum Filter

1. Cassava Dewatering Machine - Product Picture:

2. Cassava Dewatering Machine - Product Application:

Cassava & potato starch and cassava flour dewatering.

3. Cassava Dewatering Machine - Product Introduction:

Rotary vacuum filter, rotary vacuum dehydrator, cassava dewatering machine, cassava starch dewatering machine for cassava starch processing. Widely used for the dehydration in starch, modified starch, medicine, food, chemical industry etc.

4. Cassava Dewatering Machine - Product Advantage:

Vacuum dewater, high dehydration rate, easy to dry

The refined starch slurry has a high water content and cannot be directly dried, and needs to be dehydrated. GOODWAY dehydration series equipment, using a unique invention and creation method, the outer drum round rate is up to 99.95%, using vacuum suction filtration method to effectively improve the starch clarity. After dehydration, the starch is easy to be dried to ensure the quality of the finished starch.

(1) Adopt advanced constant pressure cake layer bridging principle, starch granules above 45μm, blocking rate 100%;

(2) Double pump drainage structure, starch dehydration is sufficient, water content is about 40% The vacuum drum adopts independent research and development, and the round rate is up to 99.95%;

(3) Vacuum suction filtration method can improve the purity of starch and no interlayer phenomenon compared with other dehydration methods;

(4) Adopt integrated vacuum pump + gas water separator structure to improve working efficiency by more than 10% The dehydrated starch is in the form of loose powder, which is easy to dry and guarantee the quality of finished starch. Energy efficient, energy saving over 60% compared to traditional centrifugal dewatering machines Continuous operation, no need to stop the discharge during the dehydration process, to ensure the continuity of operation;

(5) Elastic high-strength alloy scraper, tough and durable;

(6) The drum adopts stepless speed regulation, which is easy to operate and stable in operation, and can be easily adjusted according to different starch properties. No need to manually unload, reduce labor and reduce labor intensity;

5. Cassava Dewatering Machine - Technical Parameter:

|

Model number |

GD-TS-03 |

GD-TS-05 |

GD-TS-06 |

|

Filtration area |

3m2 |

5m2 |

6m2 |

|

Output |

600-900kg/hr (0.2-0.3t/h/m2) |

1000-1500kg/hr (0.2-0.3t/h/m2) |

1200-1800kg/hr (0.2-0.3t/h/m2) |

|

Drum diameter |

1250mm |

1250mm |

1600mm |

|

Drum length |

810mm |

1270mm |

1270mm |

|

Vacuum degree |

>-0.099 |

>-0.099 |

>-0.099 |

|

Final moisture content |

≤40% |

≤40% |

≤40% |

|

Feed concentration |

10-17BE° |

10-17BE° |

10-17BE° |

|

Power |

7kw |

13.2kw |

20.7kw |

|

Dimension(L×W×H)(mm) |

1500×1400×1600 |

1500×1800×1600 |

1800×1900×1900 |

| Mobile/WhatsApp: +86 185 6729 3677 Email: sale6@goodway.top | |||

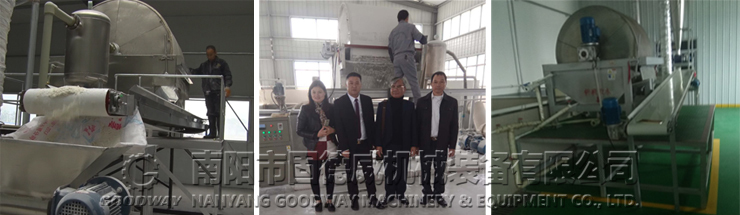

6. Cassava Dewatering Machine - Project Case:

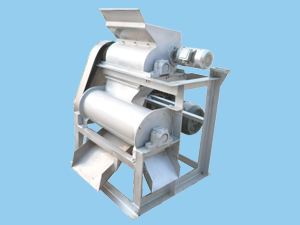

| RELATED PRODUCTS: | ||

|

|

|

| Cassava Peeler | Cassava Grater | Garri Fryer Machine |