|

|

|

SPECIALIZED IN INDUSTRIAL POTATO AND CASSAVA PROCESSING MACHINE FROM CHINA |

|

TONY ZHANG |

|

|

|

|

+86 185 6729 3677 |

|

||

|

|

SINCE 1991 | NANYANG GOODWAY MACHINERY & EQUIPMENT CO., LTD. |

|

SALE6@GOODWAY.TOP |

|

| Mobile/WhatsApp: +86 185 6729 3677 Email: sale6@goodway.top |

Cassava Starch and Flour Drying Machine - Airflow Flash Dryer

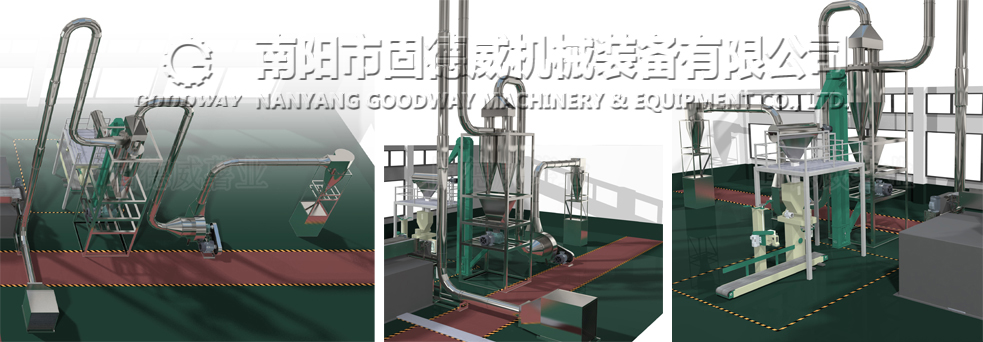

1. Airflow Flash Dryer - Product Picture:

2. Airflow Flash Dryer - Product Application:

Cassava & potato starch and cassava flour drying.

3. Airflow Flash Dryer - Product Introduction:

At present, most starch factories normally adopt airflow drying (also called flash drying), the whole process time are completed in an instant, so the internal moisture of starch granules has been dried before gelatinization, the gelatinization or degradation phenomenon of starch will not occur. Airflow drying is a cocurrent flow drying process, namely the cocurrent flow of wet powdered materials and heat flow, which consists of heat transfer and mass transfer process. When the wet starch enters flash dryer and contacts with the hot air, the hot air transfers heat to the surface of the wet starch, then from surface to interior again, the process is the heat transfer process; At the same time, the moisture in wet starch diffuses from the starch inside to the surface of starch in the form of liquid or gaseous, and then diffuses from the starch surface into the hot air through the gas film, it is a mass transfer process. Through the high temperature air and wet starch balanced heat exchange in the drying tube, do the drying of wet starch to become dry starch, then package them into standard bags and store in the warehouse after cooling. The airflow flash dryer is widely used for the drying in starch, modified starch, flour, medicine, food, chemical industry etc particle materials.

4. Airflow Flash Dryer - Product Feature:

Equipment runs safely and efficiently

(1) Vertical space installation, negative pressure operation, reducing indoor pipes, ensuring operation safety;

(2) Thickened pipe.

High quality starch product

(1) Dry at low temperature to avoid gelatinization of starch (natural cooling after mixing hot air and starch);

(2) Large air volume (10-20% larger than normal dryer air volume);

(3) Multi-point temperature measurement.

High recovery of starch

(1) Extended cone section (small diameter and long cone can be collected easily);

(2) Square cone type hopper, 85 degree large angle blanking, to ensure that all starch is collected (VS cone type);

(3) Add tail powder recycling system to fully guarantee the powder collection rate.

5. Airflow Flash Dryer - Technical Parameter:

|

Model number |

GD-HG-300 |

GD-HG-500 |

GD-HG-1000 |

GD-HG-2000 |

|

Output yield |

300kg/hour |

500kg/hour |

1000kg/hour |

2000kg/hour |

|

Power |

13kw |

22kw |

30kw |

60kw |

|

Voltage |

380V/50Hz |

380V/50Hz |

380V/50Hz |

380V/50Hz |

|

Final water content |

≤13% |

≤13% |

≤13% |

≤13% |

|

Machine Material |

Stainless steel |

Stainless steel |

Stainless steel |

Stainless steel |

|

Cover area |

30-40m2 |

30-40m2 |

40-50m2 |

70-80m2 |

| Mobile/WhatsApp: +86 185 6729 3677 Email: sale6@goodway.top | ||||

6. Airflow Flash Dryer - Project Case:

| RELATED PRODUCTS: | ||

|

|

|

| Cassava Peeler | Cassava Grater | Garri Fryer Machine |