|

|

|

SPECIALIZED IN INDUSTRIAL POTATO AND CASSAVA PROCESSING MACHINE FROM CHINA |

|

TONY ZHANG |

|

|

|

|

+86 185 6729 3677 |

|

||

|

|

SINCE 1991 | NANYANG GOODWAY MACHINERY & EQUIPMENT CO., LTD. |

|

SALE6@GOODWAY.TOP |

|

| Mobile/WhatsApp: +86 185 6729 3677 Email: sale6@goodway.top |

How to extract starch from potato

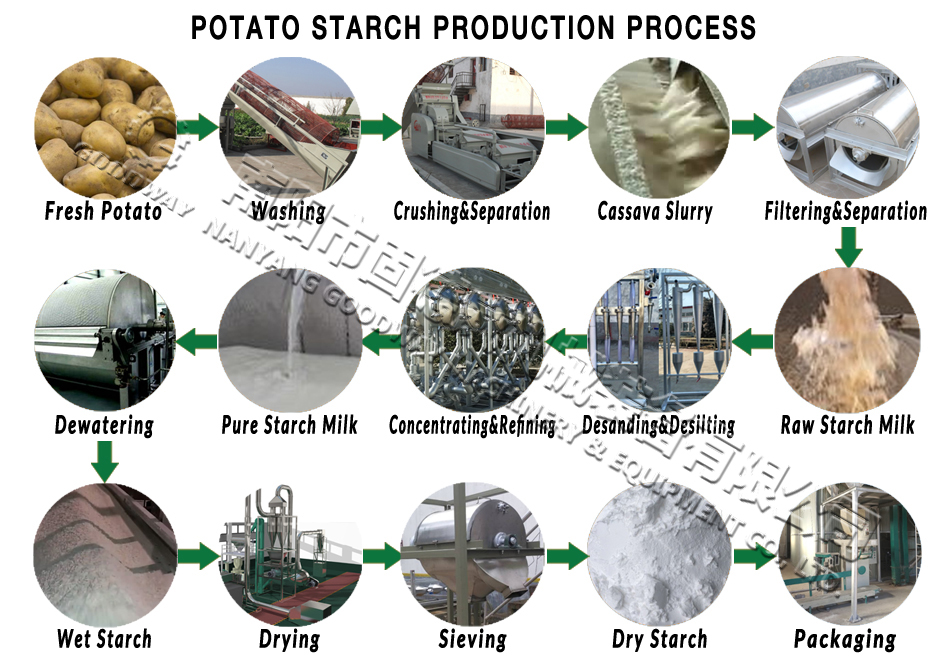

Potato starch process flowchart:

The following flowchart provides a brief overview of the main potato starch production process.

Potato Starch Production Process

Potato starch processing machine description:

The production of potato starch comprises the machines such as potato washing machine, crushing machine, fine fiber sieve, de-sanding cyclone and de-silting cyclone, starch hydro cyclone, vacuum filter, airflow flash dryer and starch packaging machine. We have provided below a brief description on the main steps of the potato starch production process.

Potato Starch Processing Machine

1. Potato washing machine: wash the fresh potato roots in clean water to remove mud, sand and other impurities. Note: The water source should be checked regularly to ensure it is not dirty or contaminated.

2. Potato crushing machine(starch extraction machine): load the crusher with washed potato roots while the engine is running to crush the potato roots into the potato slurry, and separate to remove the potato residues, to obtain uniformly smooth potato slurry. Note: The crushing drum and all food contact areas should be made from stainless steel.

|

|

| Potato Washing Machine | Potato Crushing Machine |

3. Fine fiber sieve(potato sieving machine): commonly physical operation which is used for the separation of potato residues from potato slurry by interposing a medium(filter) through which only the raw starch milk can pass (depending on the pore size and filter thickness).

4. De-sanding cyclone and de-silting cyclone: solid control equipment that separate sand and silt from the raw starch milk. De-sanding cyclone is installed before the de-silting cyclone and normally the solids diameter for de-sanding cyclone to be separated would be larger than for de-silting cyclone.

|

|

| Fine Fiber Sieve | De-sanding Cyclone and De-silting Cyclone |

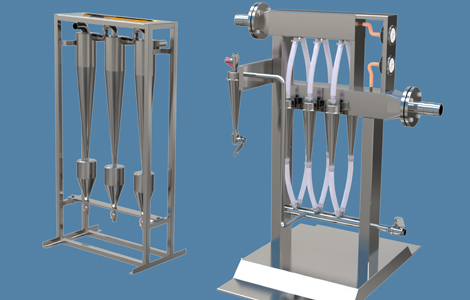

5. Starch hydro cyclone: classify, separate or sort particles in a liquid suspension based on the ratio of their centripetal force to fluid resistance, this ratio is high for dense and coarse particles, and low for light and fine particles.

6. Vacuum filter(potato starch dewatering machine): it's considered a proven technique for separating fines from liquids to realize the starch water content up to 35-40% for the next starch drying.

|

|

| Starch Hydro cyclone | Vacuum Filter |

7. Airflow flash dryer(potato starch drying machine): effectively dry the wet starch to low moisture content by principle of heat transfer exchange, and sieve to obtain fine granules of uniform size, larger particles of starch that are separated should be broken again.

8. Starch packaging machine: pack desired quantities into a woven polythene sack with a plastic lining, seal or stitch the sack to keep the starch clean and fresh during storage. Properly label the packages according to the standards of national reguArialry agencies.

|

|

| Airflow Flash Dryer | Packaging Machine |

| POTATO STARCH PROCESSING LINE PRODUCTION SCALE: | |||||

|

Dry starch per day |

Dry starch per day |

Dry starch per day |

Dry starch per day |

Dry starch per day |

Dry starch per day |

| 2-3 TONS |

6 TONS |

12 TONS |

24 TONS |

36 TONS |

48 TONS |

| The above data is calculated based on 24 hours of processing per day | |||||

| Mobile/WhatsApp: +86 185 6729 3677 Email: sale6@goodway.top | |||||

|

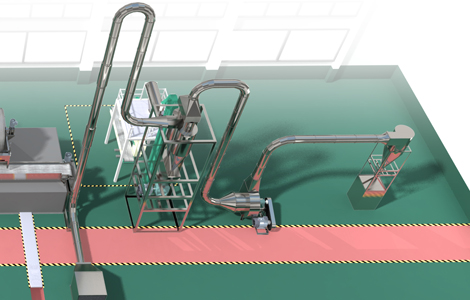

POTATO STARCH PROCESSING MACHINE PROJECT CASE: |

|

| POTATO STARCH PROCESSING MACHINE CLIENT VISITING: | ||

|

| HOT SALE PRODUCTS: | ||

|

|

|

| Cassava starch machine | Cassava flour machine | Garri processing machine |