|

|

|

SPECIALIZED IN INDUSTRIAL POTATO AND CASSAVA PROCESSING MACHINE FROM CHINA |

|

TONY ZHANG |

|

|

|

|

+86 185 6729 3677 |

|

||

|

|

SINCE 1991 | NANYANG GOODWAY MACHINERY & EQUIPMENT CO., LTD. |

|

SALE6@GOODWAY.TOP |

|

| Mobile/WhatsApp: +86 185 6729 3677 Email: sale6@goodway.top |

How to make fufu from cassava

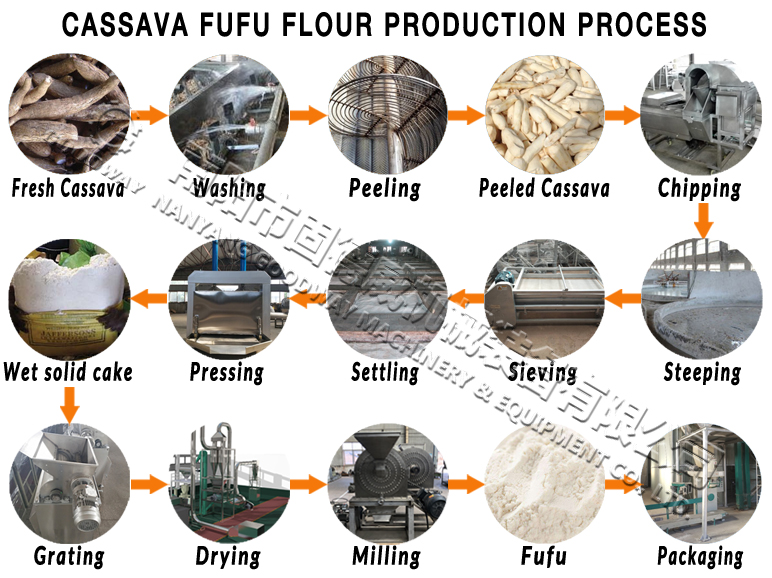

Cassava fufu process flowchart:

The following flowchart provides a brief overview of the main cassava fufu production process.

Cassava Fufu Production Process

Cassava fufu processing machine description:

The production of cassava fufu comprises the machines such as cassava washing machine, peeling machine, chipping machine, sieving machine, hydraulic press, cassava grating machine, cassava drying machine and packaging machine. We have provided below a brief description on the main steps of the cassava fufu production process.

1. Cassava washing machine: wash the fresh cassava roots in clean water to remove mud, sand and other impurities. Note: the water source should be checked regularly to ensure it is not dirty or contaminated.

2. Cassava peeling machine: wash the cassava roots to remove the surface sand, silt, and peel the cassava roots to remove the outer brown skin and partial inner thick cream layer, also avoid over damaging of raw materials. Note: If you want to remove the inner thick cream layer completely, it's neccessary to use manpower or soak the cassava tubers in water then remove it by handwork.

|

|

| Cassava Washing Machine -Cassava Washer |

Cassava Peeling Machine -Cassava Peeler |

3. Cassava chipping machine: reduce the size of cassava pieces to produce thinner and more uniform slices than chipping by hand.

4. Fermentation(manpower): steeping or fermenting the whole cassava roots or cutted cassava chips in water to ferment for a maximum of three days, depending on ambient temperature.

Note: during steeping, fermentation decreases the PH, softens the roots, and helps to reduce potentially toxic cyanogenic compounds.

5. Cassava sieving machine(vibration sieve): after steeping, using a vibration sieve to separate fibrous materials to control size of particles, finally obtain the uniform size of particles.

|

|

| Cassava Chipping Machine -Cassava Chipper |

Cassava Sieving Machine |

6. Sedimentation(manpower): the sieved mash is allowed to sediment in a large container for about 24 hours, allow fufu mash to be concentrated before decanting, after sedimentation, the water is poured off while the fine, clean sediment (mainly starch) is dewatered using a high powered Press.

7. Cassava dewatering machine(hydraulic press dewater): fermented paste is filled into hessian or polypropylene sacks and Load the bags directly on to a hydraulic press. Under control of hydraulic station and electric cabinet to lift and press the jack handle up and down until it becomes hard to move. Repeat the process several times each day until no more water comes out of the bag to produce a firm wet cake(Pressed mash may be pack and sold as wet fufu).

8. Cassava grating machine: use motorized grater to pulverise wet solid cakes(after pressing) into smaller particle size and increase the surface area for easy drying.

|

|

| Cassava Dewatering Machine -Hydraulic Press |

Cassava Grating Machine -Cassava Grater |

9. Cassava fufu drying machine(airflow flash dryer): effectively dry the wet slurry to low moisture content by principle of heat transfer exchange, the drying process is more reliable and of higher quality.

10. Fufu milling machine: mill the dried coarse fufu flour to produce fine fufu flour. Milling can be done using a roller mill machine, and the size of final fine flour can be customized according to customers' requirements, the standard one is 80-100mesh.

|

|

| Cassava Fufu Drying Machine | Fufu Milling Machine |

| CASSAVA FUFU PROCESSING LINE PRODUCTION SCALE: | |||||

| Dry fufu per day |

Dry fufu per day |

Dry fufu per day |

Dry fufu per day |

Dry fufu per day |

Dry fufu per day |

| 4-5 TONS | 7 TONS | 12 TONS | 24 TONS | 36 TONS | 48 TONS |

| The above data is calculated based on 24 hours of processing per day | |||||

| Mobile/WhatsApp: +86 185 6729 3677 Email: sale6@goodway.top | |||||

| CASSAVA FUFU PROCESSING MACHINE PROJECT CASE: |

|

|

CASSAVA FUFU PROCESSING MACHINE SHIPPING: |

|

|

CASSAVA FUFU PROCESSING MACHINE CLIENT VISITING: | |||

| |||

| Nigeria Client | Cameroon Client | Indonesia Client | Guatemala Client |

| HOT SALE PRODUCTS: | ||

|

|

|

| Cassava starch machine | Cassava flour machine | Garri processing machine |